Extension Cords - Safety and how to choose the right size.

I feel this is a topic that is not discussed frequently enough. We rely on machine manufactures to provide proper cords for the equipment they make, and trust they are the proper size and length for the power demands for that equipment. However, sometimes we need a longer cord run to reach a power source, and sometimes machines don't even come with cords, so we have to provide our own.

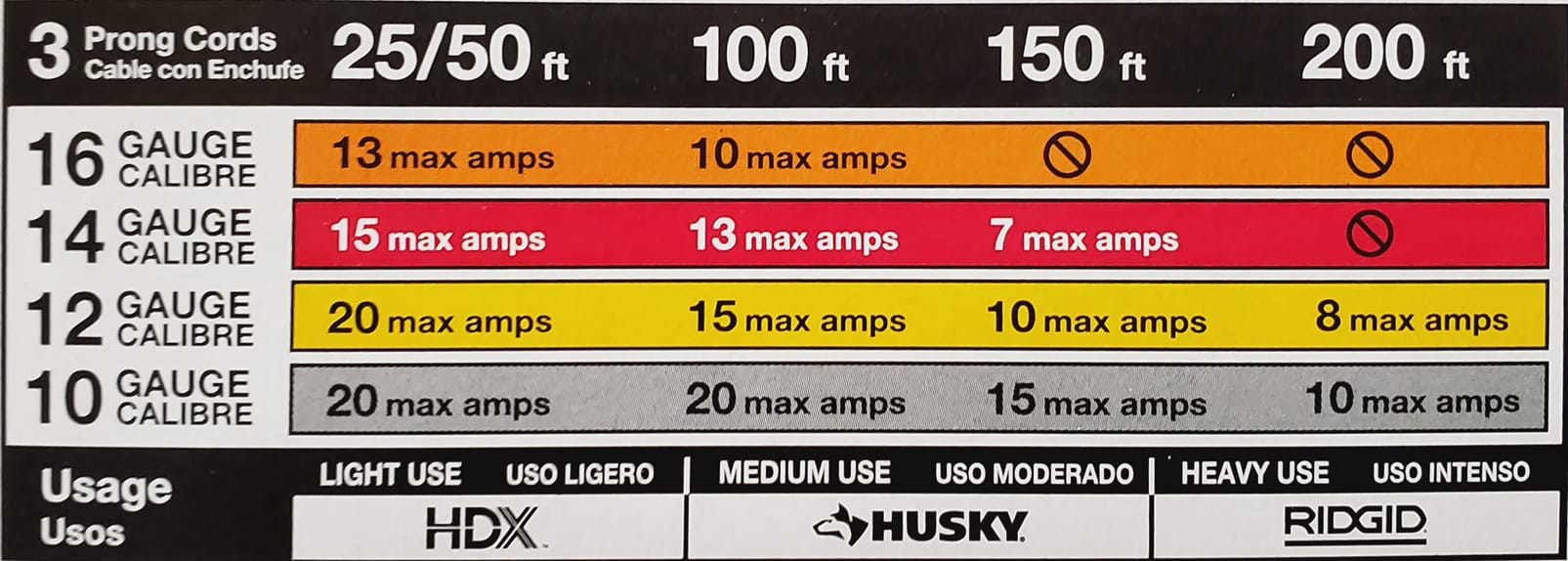

I was shopping around home depot last week for a new cord for a 10" Clean Scrub TM3 CRB machine. One of my techs ran over the cord and cut open the outer protective casing, then we lent it to a local cleaner and his tech did the same, but much worse, exposing the actual wires, so definitely time for a new cord. As I was browsing through the sizes and colors, I found this chart.

Although I knew the basics of choosing a cord, I couldn't remember the actual specifications. So needless to say, I was happy to find this. We wanted a 50 foot cord, so based on this chart, pulling up to 20 amps, we chose a 12 gauge cord.

Another example would be if you already have a portable extractor, CRB, Cimex Machine, or other equipment with a 50 foot 12 gauge cord, but you want to go an extra 50 feet. Can you add a second 12 gauge cord? The answer is NO! You must move up to a 10 gauge cord for the 50 feet closest to the power source. Have you ever unplugged your cord from the wall and it was extremely hot?! The best way to go to prevent issues would be to get rid of the 12 gauge cord and get two 10 gauge cords if you plan to use 100 feet total.

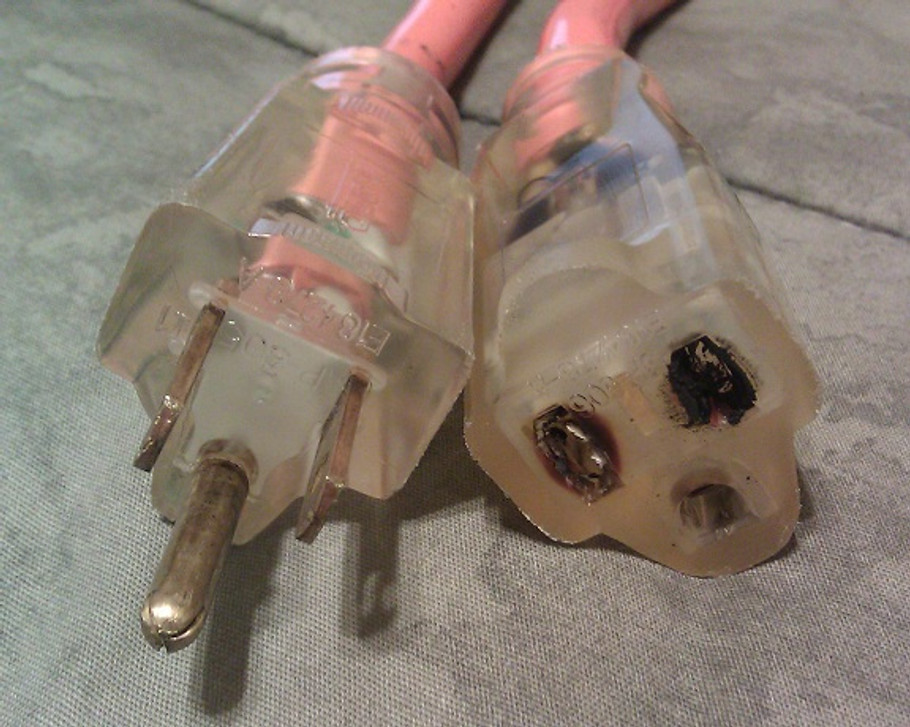

If your cord id not rated for the power it is drawing, you run a high risk of fire. First, the casing or plug end starts to melt. If this happens within the cord, then 2 wires may come in contact and start an electrical fire. Circuit breakers are designed to prevent this but it still happens in the real world. Alternatively, cord ends may begin to melt if not assembled tight enough, or on a replacement end, the screws may be loose causing it to heat up and melt. Third, if your cord connections get wet from water dripping over them, the same can happen. To prevent cord end on the back of you portable extractor from getting wet, we suggest getting cord protectors, like these...Picture to the left. These will help prevent cords fusing together, melting, or burning, like the picture to the right...

Lastly, when using your cords, do not leave them wound up. Just like your vacuum hose, you want to spread them out as much as possible. For different reason of course. The vacuum hose will have less air friction when straight, giving you better suction. The power cords should be straight and spread out to minimize heat and resistance. This will help your equipment operate more consistently under load, and will also prevent damage to the cords from getting too hot.

I hope this info helps. If you have any comments you would like to add to this post, please send me an email at dave@cleanprosupply.com and I will be happy to include the info.